- Home Page

- Company Profile

-

Our Products

- Strapping Machine

- Case Sealer Machine

- Induction Wads & Aluminum Foils

- Battery Operator Tool

- Battery Powered Composite-Lashing Strapping Tool

- Battery Operator Strapping Tool

- DD 19 A Battery Operated Strapping Tool

- JDC16 Battery Operated Strapping Tool

- PR1T Battery Operated Strapping Tool

- ZP CT 32 B Battery Operated Strapping Tool

- ZP93 Battery Operated Strapping Tool

- Battery Powered Tool DD 19 A

- Battery Powered Tool JDC16

- Battery Powered Tool PR1T

- Battery Powered Tool ZP CT 32 B

- Battery Powered Tool ZP93

- Stretch Wrapping Machine

- Coil Wrapping Machine

- Spiral Stretch Wrapping Machine

- Pallet Stretch Wrapping Machine

- Horizontal Fabric Roll Stretch Wrapping Machine

- Box Stretch Wrapping Machine

- DBC800S Box Stretch Wrapping Machine

- DBC800 Box Stretch Wrapping Machine Pneumatic Machine

- Pallet Wrapping Machine

- BM500 Stretch Film Dispenser

- W110 Stretch Film Dispenser Machine

- Box Stretch Wrapping Machine DBC800S

- Box Stretch Wrapping Machine Pneumatic DBC800 Machine

- Pallet Wrapping Machine

- Stretch Film Dispenser BM500

- Stretch Film Dispenser W110 Machine

- Pneumatic Plier, Pinner & Hog Ringer

- Pneumatic Hog Ringer PRO-HR24TC

- PRO-HTTGA Hand Tacker

- Pneumatic Pinner OM XPRO-PP6435

- Pneumatic Pinner PRO-PP6435

- Pneumatic Hog Ringer PRO-HR24LN

- ME XPRO-HT8016 Rocama Hand Tacker

- PRO-HT5014 Hand Tacker

- Pneumatic Pinner ECO-PP6422

- XPRO-PL77916BJ Pneumatic Plier

- Pneumatic Plier JK XPRO-PL77922LM

- Pneumatic Plier PRO-PL77925BJ

- Pneumatic Plier JK XPRO-PL77916LM

- Pneumatic Plier JK XPRO-PL77922BJ

- Pneumatic Plier JK XPRO-PL59025

- Pneumatic Plier PRO-PL77925LJ

- Pneumatic Plier PRO-PL77925SJ

- Pneumatic Plier XPRO-PL77916BJ

- Pneumatic Composite Pinner XPRO-PPRIP25

- Pneumatic Hog Ringer Pro-HR24

- BOPP Tape

- Shrink Film

- Continuous Bag Sealing Machine

- Bag Sealing Machine

- Continuous Band Sealer CSi 15 H HV

- Continuous Band Sealer CS 15 PID H HV

- Horizontal Continuous Band Sealer Csi 3 H HV

- Continuous Band Sealer CS 3 H Digital

- Continuous Band Sealer CS 3 PID H HV

- Continuous Band Sealer CS 15 V Digital

- Continuous Band Sealer CS 30 PID

- Continuous Bag-Pouch Sealing Machine 7209

- Continuous Bag-Pouch Sealing Machine 7205

- Pnumatic Bag Sealing Machine

- Pneumatic Strapping Tool

- Steel Strap & Tool

- Sealless Tools

- Pneumatic Sealer Gp S19

- S259 Steel Strapping Tensioner

- Steel Strapping Seal

- C3160 Steel Strap Sealer

- Steel Strapping Tensioner S300

- Steel Strap Sealer C3180

- Steel Strapping Cutters H410

- Steel Strapping Cutters H300

- Pneumatic Tensioner Gp T 1932

- Pneumatic Sealer Gp S32

- Steel Strap Sealer C3160

- Steel Strapping Cutters H200

- Steel Strap Tensioner

- Steel Strapping Tensioner S227

- Steel Strapping Tensioner S246

- Pneumatic Combination Tool

- Steel Strapping Tensioner S259

- Steel Strapping Tensioner S249

- Steel Strapping Tensioner S290

- Sealless Combination Tools Sl200

- GP S32 Pneumatic Sealer

- ECO-PB16G64 Pneumatic Tensioner

- C3180 Steel Strap Sealer

- Stretch Film

- Vacuum Machine & Pouches

- Foil Sealing Machine

- Liquid Filling Machine

- Fully Automatic Liquid Filling Machine

- Fill Sealing Machine

- Semi Drum Filling Machine - Weighfil 230 CPSS

- Single Head Load Cellbased Filling Machine

- Industrial Liquid Filling Machine

- Semi Automatic Liquid Filling Machine

- Packaging Machine Line

- Two Head PLC Liquid Filling Machine

- Packaging Machine Line

- Two Head Liquid Filling Machine

- Air Cool Induction Cap Sealing Machine

- Pneumatic Nailer & Brad Nailer

- Pneumatic Brad Nailer ECO-PB16G50

- Pneumatic Brad Nailer ECO-PB18G32

- Pneumatic Nailer PRO-PN2150

- Pneumatic Nailer PRO-PN3390V2

- Pneumatic Composite Brad Nailer Xpro-PB1240P25

- Pneumatic Brad Nailer ECO-PB16G64

- Pneumatic Brad Nailer ECO-PB18G50NN

- Pneumatic Nailer ECO-PN2357

- Pneumatic Brad Nailer PRO-PB18G32

- Pneumatic Brad Nailer ECO-PB16G50UD

- Pneumatic Brad Nailer ECO-PB18G50

- Pneumatic Nailer ECO-PN2970

- Pneumatic Nailer ECO-PN3383

- Pneumatic Nailer PRO-PN2357

- Pneumatic Brad Nailer PRO-PB18G50V3

- Pneumatic Brad Nailer PRO-PB18G50V2

- Pneumatic Nailer PRO-PN2970

- Pneumatic Nailer PRO-PN2965

- Pneumatic Nailer PRO-PN38100

- Pneumatic Nailer PRO-PN38130

- Edge Protector

- Cord Strap & Tool

- Aluminum Foils

- Strapping Dispenser

- Manual Top Sealer

- Top Sealer TS-250-3P

- Top Sealer TS-150-101SQ

- Top Sealer TS-150-101T

- Top Sealer TS-150-58-2C

- Manual Rotary Cup Sealing Machine

- Top Sealer Ts-300-5p

- Top Sealer Ts-200-69-2c

- Top Sealer Ts-200-80-2c

- Top Sealer Ts-150-123c

- Top Sealer Ts-150-80c

- Top Sealer Ts-150-95c

- Top Sealer Ts-300-8p

- Top Sealer Ts-200-142t-2p

- Top Sealer Ts-200-142t

- Semi Tin Cap Sealing Machine

- Pneumatic Stapler Machine

- PET Strap Dispenser

- Air Boxer, Hand Boxer & Flooring Nailer

- Air Boxer PRO-AB3522COMBI

- Air Boxer PRO-AB3518COMBI

- Flooring Nailer PT Manual XPRO-FN1838 Q500

- Hand Boxer PRO-HB3522COMBI

- Hand Boxer PRO-HB3518COMBI

- Flooring Nailer PT Pneumatic XPRO-FN1838 Q550AL

- Bottom Closer Manual

- Flooring Nailer PT Manual XPRO-FN1650 H330

- Flooring Nailer PT Pneumatic XPRO-FN1650 250F

- Brad Nailer

- Strapping Roll

- Fill Air RF Bag

- Box Strapping Machine

- Bag Closing Machine

- Coding Machine

- Cryovac Shrink Film

- Cup Sealing Machine

- adhesive filling machine

- Pet Strap & Tool

- PP Strap & Tool

- Shrink Chambers, L Sealer With Shrink Tunnel

- Shrink Tunnel

- Web Sealer Shrink Machine

- MPPL06X06 Shrink Tunnel Machine

- Shrink Tunnel Mppl20x12

- Shrink Tunnel Mppl20x20

- Shrink Machine For Water Bottle Label And Cap

- Gas Shrink Gun

- Shrink Tunnel Floor Model Mppl06x06

- Shrink Tunnel MPPL12X12

- Shrink Tunnel Mppl14x16

- Shrink Tunnel Mppl16x12

- Shrink Tunnel Mppl16x16

- Shrink Tunnel Floor Model Mppl08x08

- Shrink Tunnel Floor Model Mppl12x08

- Gas Heat Shrink Gun

- 24X08XX06 Floor Model Shrink Tunnel Machine

- 24X12X08 Shrink Tunnel Machine

- 30X08X06 Floor Model Shrink Tunnel Machine

- 30X12X08 Shrink Tunnel Machine

- 30X12X12 Floor Model Shrink Tunnel Machine

- 30X16X10 Shrink Wrapping Machine

- Leg Type Model Shrink Tunnel Machine

- 36X12X18 Shrink Wrapping Machine

- 36X18X14 Shrink Wrapping Machine

- 39X14X17 Shrinnk Wrapping Machine

- 24X16X8 Shrink Wrapping Machine For Label

- Floor Model Shrink Tunnel Machine

- Shrink Tunnel Floor Model Machine

- Shrink Tunnel Leg Type Model Machine

- Foot Operated Sealer

- Hand Operated Sealer

- Electric Stapler

- Hand Tacker

- Pneumatic Stapler

- Pneumatic Stapler NEO-PS1013J

- Pneumatic Stapler PRO-PS9716

- Pneumatic Stapler PRO-PS8016

- Pneumatic Stapler ECO-PS1013J

- Pneumatic Stapler PRO-PS1013J

- Pneumatic Stapler FA PRO-PSHS16

- Pneumatic Stapler PRO-PS9240

- Pneumatic Stapler NEO-PS10050

- Pneumatic Stapler Prebena XPRO-PS10050

- Pneumatic Stapler OM XPRO-PS8016FA

- Pneumatic Stapler PRO-PS9040

- Pneumatic Stapler ECO-1013JV2

- Pneumatic Stapler PRO-PS10050V2

- Pneumatic Stapler ECO-PS1013F

- Pneumatic Stapler ECO-PS8016LN

- Pneumatic Stapler ECO-PS9040COMBI

- Pneumatic Stapler ECO-PS10050E2

- Pneumatic Stapler FA PRO-PS5416

- Pneumatic Stapler JK XPRO-PS8016RALM

- Pneumatic Stapler NEO-PS8016

- Pneumatic Stapler PRO-PS8016V2

- Pneumatic Stapler ECO-PS8016

- Pneumatic Stapler ECO-PS1013JV2

- Pneumatic Stapler OM XPRO-PS8016

- Pneumatic Stapler PRO-PS8016LNV2

- Pneumatic Stapler ECO-PS7116

- Pneumatic Stapler OM XPRO-PS8016BLM

- Pneumatic Stapler ECO-PS10050

- Pneumatic Stapler OM XPRO-PS8016LN

- Pneumatic Stapler PRO-PS2312

- Pneumatic Stapler PRO-PS9225

- Pneumatic Stapler PRO-PS1013FV2

- Pneumatic Stapler PRO-PS16WC38V2

- Pneumatic Stapler OM XPRO-PS16WC38FA

- Electric Brad Nailer

- Concrete Nailer

- Hammer Tacker

- Pneumatic Corrugated Fastener

- Staple Remover

- Bag Sealing Machine-Impulse Sealer

- 400 FHED Foot Sealer

- 200 FP Foot Operated Sealers Premium Series

- 190 HW Hand Operated Sealers

- AIS 450 Automatic Impulse Sealer

- 300 HW Hand Operated Sealers

- 200 FE Foot Operated Sealers Premium Series

- 400 FD Foot Sealers

- 200 Dv2 Hand Operated Sealers

- 500 FE Foot Operated Sealers

- 900 F Foot Sealers

- 400 FED Foot Operated Sealers

- 200 F Foot Operated Sealers Premium Series

- 900 MSE Mobile Sealing Machine

- 300 HH Hand Operated Hot Bar Sealer

- 300 FPD Foot Sealers

- 300 FP Foot Sealers

- Pneumatic Sealing Machine

- QS400T Impulse Tong Sealer

- 600 FE Foot Sealers

- 400 F Foot Operated Sealers Premium Series

- 300 Delta Hand Operated Sealers

- 600 HB Hand Operated Sealers

- 500 F Foot Sealer

- 400 HB Hand Operated Sealers

- 300 FE Foot Sealers Premium Series

- 300 FD Foot Operated Sealer

- 250 Delta Hand Operated Sealers

- QS300PNI Pneumatic Retort Sealer

- 300 FED Foot Operated Sealers

- QS400TH Hot Bar Tong Sealer

- 300 HB Hand Operated Sealers

- 500 HB Hand Operated Sealers

- QS 300 F Foot Operated Sealers Premium Series

- 200 FH Series Foot Sealer

- 600 F Foot Sealers

- 400 D Hand Operated Sealers

- 200 HB Hand Operated Sealers

- Pneumatic Coil Nailer & Brad Nailer

- Continuous Bag Sealing Band Sealing Machine

- Air Bubble Film Wrap

- Semi-Automatic Box Strapping Machine

- Fully Automatic Strapping Machine

- Hot Air Gun

- Weldy Energy HT3400 Hot Air Hand Tool Machine

- Weldy HG 210 B Hot Air Hand Tool Machine

- Weldy HG 330 A Hot Air Hand Tool Machine

- Weldy HG 330 B Hot Air Hand Tool Machine

- Weldy HG 330 S Hot Air Hand Tool Machine

- Weldy HG 530 A Hot Air Hand Tool Machine

- Weldy HG 530 S Hot Air Hand Tool Machine

- Weldy HT 330 S Hot Air Hand Tool Machine

- Weldy HT 1600 Hot Air Hand Tool Machine

- Weldy HT 1600 D Hot Air Hand Tool Machine

- Weldy HT 530 A Hot Air Hand Tool Machine

- Weldy Energy HT3400 Machine

- Weldy HG 210 B Machine

- Weldy HG 330 A Machine

- Weldy HG 330 B Machine

- Weldy HG 330 S Machine

- Weldy HG 530 A Machine

- Weldy HG 530 S Machine

- Weldy HT 330 S Machine

- Weldy HT 530 A Machine

- Weldy HT 1600 D Machine

- Weldy HT 1600 Machine

- Chamber Type Shrink Machine

- Semi-Automatic Shrink Machine

- Auto Shrink Machine

- Web Shrink Machine

- Mini Model Web Sealer With Shrink Wrapping Machine

- Web Sealer With Shrink Wrapping Machine For Box

- Web Sealer With Shrink Wrapping Machine

- Web Sealer Shrink Wrapping Machine

- Web Sealer with Shrink Wrapping Machine for Box 48 x 48 x 30 Machine

- Web Sealer with Shrink Wrapping Machine for Box

- Web Sealer with Shrink Wrapping Machine Mini Model

- Web Sealer with Shrink Wrapping Machine

- Continuous Bag Sealer

- Automatic Plastic Bag Vertical Band Sealer

- PSCH7200 Heavy Duty Horizontal Continuous Pouch Sealer

- SCS 3H Smart Continuous Sealer Horizontal

- Vertical Continous Bag Sealing Machine

- Vertical Continous Bag Sealing Machine

- CS Series Continuous Sealer Gas Flushing

- Vertical Continuous Sealer

- Jack Type Vertical Continuous Sealer Machine

- Vertical Heavy Duty Continuous Pouch Sealer Machine

- 8 Continuous Bag Sealer

- Continuous Pouch Sealer Heavy Duty Horizontal

- Continuous Pouch Sealer Heavy Duty Vertical

- Continuous Pouch Sealer Heavy Duty

- Continuous Sealer Gas Flushing

- Continuous Sealer Horizontal

- Continuous Sealer Vertical Model for 20 Kg

- Continuous Sealer Vertical

- Jack type Vertical Continuous Sealer Machine

- AQD 19 Pneumatic Pet PP Strap Tool

- Induction Sealing Machine

- Air Cool Induction Cap Sealing Machine

- IS 50C 120C Induction Sealers

- IS 80P Induction Sealers

- IS 130C Induction Sealers

- Manual Foil Sealing Machine

- Air Cool Induction Cap Sealing Machine

- IS 50C 120C Induction Sealing Machine

- IS 80P Induction Sealing Machine

- IS 130C Induction Sealing Machine

- Manual Foil Sealing Machine

- Induction Wad Sealing Machine

- Hand Sealer Pedal Machine

- Vacuum Packaging Machine

- Labelling Machine

- Top Sealer

- Printing Machine

- Packing Materials

- Air Bubble Roll

- Clear Air Bubble Roll

- Aluminium Foil

- Printed Round Aluminium Foil

- BOPP Tape

- Steel Buckle

- Cord Strap Buckle

- Cord Strap

- Edge Protector

- Brown Edge Protector

- Glue Stick

- Induction Wad For Cap

- Round Induction Wad

- LDPE Roll

- Clear LDPE Roll

- PET Strap

- Polyole Roll

- Clear Polyole Roll

- Transparent Polyole Roll

- PP Strap

- PET Preform

- PVC Shrink Roll

- PVC Shrink Sleeve

- Serrated Seals And Seals

- Stretch Film

- White Thread

- Vacuum Pouch

- Rectangular Vacuum Pouch

- Transparent Vacuum Pouch

- BOPP Tape Dispenser

- Wad And Foils

- Hand Tools

- Contact Us

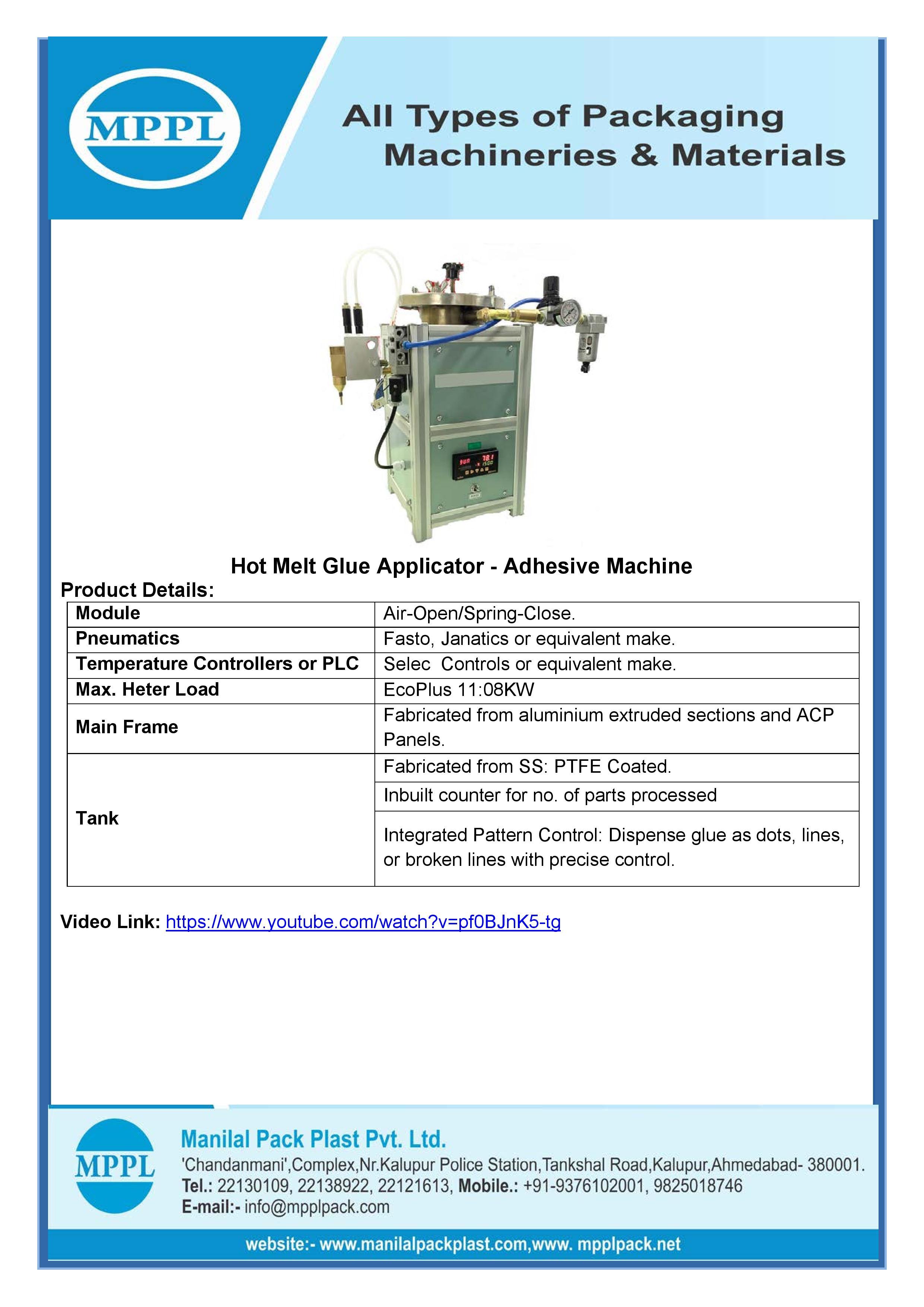

Hot Melt Glue Applicator Adhesive Machine

250000.00 INR/Unit

Product Details:

- Power Supply Single Phase

- Features Corrosion Resistant, User-Friendly Interface, Energy Efficient

- Application Carton Sealing, Packaging, Product Assembly, Bookbinding

- Filling Range Up to 30 kg/h

- Usage Industrial, Commercial

- Noise Level Below 70 dB

- Type Hot Melt Glue Applicator Adhesive Machine

- Click to View more

X

Hot Melt Glue Applicator Adhesive Machine Price And Quantity

- 250000.00 INR/Unit

- 1 Unit

Hot Melt Glue Applicator Adhesive Machine Product Specifications

- Mild Steel

- Electric

- Yes

- Hot Melt Glue Applicator Adhesive Machine

- 3.5 kW

- 110 kg

- Up to 30 kg/h

- PLC Control

- Carton Sealing, Packaging, Product Assembly, Bookbinding

- Corrosion Resistant, User-Friendly Interface, Energy Efficient

- 950 x 600 x 1200 mm

- 20-30 kg/h

- Single Phase

- Automatic

- Below 70 dB

- High Efficiency, Easy Operation, Stable Performance

- Adhesive Applicator

- Hot Melt

- 220-240 V

- Industrial, Commercial

- Blue & White

Hot Melt Glue Applicator Adhesive Machine Trade Information

- Cash Advance (CA)

- 10-15 Days

- Asia

- All India

Product Description

Hot Melt Glue Applicator Adhesive Machine

Product Details

| Module | Air-Open/Spring-Close. |

| Pneumatics | Fasto, Janatics or equivalent make. |

| Temperature Controllers or PLC | Selec Controls or equivalent make. |

| Max. Heter Load | EcoPlus 11:08KW |

| Main Frame | Fabricated from aluminium extruded sections and ACP Panels. |

| Tank | Fabricated from SS: PTFE Coated. |

| Capacity | Inbuilt counter for no. of parts processed |

| Power | Integrated Pattern Control: Dispense glue as dots, lines, or broken lines with precise control. |

Product Video Link: https://www.youtube.com/watch?v=pf0BJnK5-tg

Advanced Digital Temperature Control

Benefit from precise temperature management using the digital LED display and PLC system. The operator can easily adjust the temperature up to 220C, ensuring optimal adhesive consistency for diverse applications. This digital system contributes to stable performance, reducing waste and increasing bonding quality across a range of packaging and assembly tasks.

Efficient, High-Volume Hot Melt Application

Designed for demanding environments, this applicator handles up to 30 kg of adhesive per hour with a 10-liter tank. The gear pump system and customizable nozzles allow for continuous, controlled flow, while the fast heating time minimizes downtime. This guarantees effective performance for industrial packaging, bookbinding, or carton sealing operations.

Safety and Mobility in One Package

Equipped with overheat protection, emergency stop switch, and a user-friendly interface, this machine prioritizes operator safety. Lockable wheels enable effortless movement and stable positioning, making this applicator ideal for dynamic industrial and commercial settings where flexibility and safety are crucial.

FAQs of Hot Melt Glue Applicator Adhesive Machine:

Q: How does the Hot Melt Glue Applicator ensure safe operation during use?

A: The machine is equipped with overheat protection and an emergency stop switch to safeguard against operational hazards, ensuring a safe working environment for operators even during extended use.Q: What are the main benefits of using a digital temperature control and LED display?

A: Digital temperature control and the LED display provide precision and real-time monitoring, allowing accurate temperature adjustments up to 220C. This ensures consistent adhesive quality, minimizing errors and improving efficiency.Q: Where can this adhesive machine be used most effectively?

A: This hot melt applicator is ideal for industrial and commercial applications such as carton sealing, bookbinding, packaging, and product assembly, delivering reliable adhesive performance across various sectors.Q: What is the process for customizing the nozzle type?

A: Nozzles can be customized to suit specific application requirements or adhesive patterns. For customization, you may specify your needs to the supplier during ordering, ensuring optimized glue application for your process.Q: When is maintenance required to achieve the machines 5-year service life?

A: Regular maintenance, including cleaning the tank, inspecting the gear pump, checking hoses, and verifying system settings, should be performed as recommended in the manual to maximize longevity and consistent output.Q: What makes this applicator suitable for high-capacity production environments?

A: With a 10-liter tank, gear pump system, and up to 30 kg/h adhesive output, the machine manages large volumes efficiently. Its automatic PLC control ensures continuous, stable operation in demanding production settings.Q: How easy is it to operate and relocate the machine within a facility?

A: The applicator features a user-friendly interface for easy operation and is mounted on lockable wheels, allowing for safe and convenient relocation as needed within industrial or commercial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese