- Home Page

- Company Profile

-

Our Products

- Strapping Machine

- Case Sealer Machine

- Induction Wads & Aluminum Foils

- Battery Operator Tool

- Battery Powered Composite-Lashing Strapping Tool

- Battery Operator Strapping Tool

- DD 19 A Battery Operated Strapping Tool

- JDC16 Battery Operated Strapping Tool

- PR1T Battery Operated Strapping Tool

- ZP CT 32 B Battery Operated Strapping Tool

- ZP93 Battery Operated Strapping Tool

- Battery Powered Tool DD 19 A

- Battery Powered Tool JDC16

- Battery Powered Tool PR1T

- Battery Powered Tool ZP CT 32 B

- Battery Powered Tool ZP93

- Stretch Wrapping Machine

- Coil Wrapping Machine

- Spiral Stretch Wrapping Machine

- Pallet Stretch Wrapping Machine

- Horizontal Fabric Roll Stretch Wrapping Machine

- Box Stretch Wrapping Machine

- DBC800S Box Stretch Wrapping Machine

- DBC800 Box Stretch Wrapping Machine Pneumatic Machine

- Pallet Wrapping Machine

- BM500 Stretch Film Dispenser

- W110 Stretch Film Dispenser Machine

- Box Stretch Wrapping Machine DBC800S

- Box Stretch Wrapping Machine Pneumatic DBC800 Machine

- Pallet Wrapping Machine

- Stretch Film Dispenser BM500

- Stretch Film Dispenser W110 Machine

- Pneumatic Plier, Pinner & Hog Ringer

- Pneumatic Hog Ringer PRO-HR24TC

- PRO-HTTGA Hand Tacker

- Pneumatic Pinner OM XPRO-PP6435

- Pneumatic Pinner PRO-PP6435

- Pneumatic Hog Ringer PRO-HR24LN

- ME XPRO-HT8016 Rocama Hand Tacker

- PRO-HT5014 Hand Tacker

- Pneumatic Pinner ECO-PP6422

- XPRO-PL77916BJ Pneumatic Plier

- Pneumatic Plier JK XPRO-PL77922LM

- Pneumatic Plier PRO-PL77925BJ

- Pneumatic Plier JK XPRO-PL77916LM

- Pneumatic Plier JK XPRO-PL77922BJ

- Pneumatic Plier JK XPRO-PL59025

- Pneumatic Plier PRO-PL77925LJ

- Pneumatic Plier PRO-PL77925SJ

- Pneumatic Plier XPRO-PL77916BJ

- Pneumatic Composite Pinner XPRO-PPRIP25

- Pneumatic Hog Ringer Pro-HR24

- BOPP Tape

- Shrink Film

- Continuous Bag Sealing Machine

- Bag Sealing Machine

- Continuous Band Sealer CSi 15 H HV

- Continuous Band Sealer CS 15 PID H HV

- Horizontal Continuous Band Sealer Csi 3 H HV

- Continuous Band Sealer CS 3 H Digital

- Continuous Band Sealer CS 3 PID H HV

- Continuous Band Sealer CS 15 V Digital

- Continuous Band Sealer CS 30 PID

- Continuous Bag-Pouch Sealing Machine 7209

- Continuous Bag-Pouch Sealing Machine 7205

- Pnumatic Bag Sealing Machine

- Pneumatic Strapping Tool

- Steel Strap & Tool

- Sealless Tools

- Pneumatic Sealer Gp S19

- S259 Steel Strapping Tensioner

- Steel Strapping Seal

- C3160 Steel Strap Sealer

- Steel Strapping Tensioner S300

- Steel Strap Sealer C3180

- Steel Strapping Cutters H410

- Steel Strapping Cutters H300

- Pneumatic Tensioner Gp T 1932

- Pneumatic Sealer Gp S32

- Steel Strap Sealer C3160

- Steel Strapping Cutters H200

- Steel Strap Tensioner

- Steel Strapping Tensioner S227

- Steel Strapping Tensioner S246

- Pneumatic Combination Tool

- Steel Strapping Tensioner S259

- Steel Strapping Tensioner S249

- Steel Strapping Tensioner S290

- Sealless Combination Tools Sl200

- GP S32 Pneumatic Sealer

- ECO-PB16G64 Pneumatic Tensioner

- C3180 Steel Strap Sealer

- Stretch Film

- Vacuum Machine & Pouches

- Foil Sealing Machine

- Liquid Filling Machine

- Fully Automatic Liquid Filling Machine

- Fill Sealing Machine

- Semi Drum Filling Machine - Weighfil 230 CPSS

- Single Head Load Cellbased Filling Machine

- Industrial Liquid Filling Machine

- Semi Automatic Liquid Filling Machine

- Packaging Machine Line

- Two Head PLC Liquid Filling Machine

- Packaging Machine Line

- Two Head Liquid Filling Machine

- Air Cool Induction Cap Sealing Machine

- Pneumatic Nailer & Brad Nailer

- Pneumatic Brad Nailer ECO-PB16G50

- Pneumatic Brad Nailer ECO-PB18G32

- Pneumatic Nailer PRO-PN2150

- Pneumatic Nailer PRO-PN3390V2

- Pneumatic Composite Brad Nailer Xpro-PB1240P25

- Pneumatic Brad Nailer ECO-PB16G64

- Pneumatic Brad Nailer ECO-PB18G50NN

- Pneumatic Nailer ECO-PN2357

- Pneumatic Brad Nailer PRO-PB18G32

- Pneumatic Brad Nailer ECO-PB16G50UD

- Pneumatic Brad Nailer ECO-PB18G50

- Pneumatic Nailer ECO-PN2970

- Pneumatic Nailer ECO-PN3383

- Pneumatic Nailer PRO-PN2357

- Pneumatic Brad Nailer PRO-PB18G50V3

- Pneumatic Brad Nailer PRO-PB18G50V2

- Pneumatic Nailer PRO-PN2970

- Pneumatic Nailer PRO-PN2965

- Pneumatic Nailer PRO-PN38100

- Pneumatic Nailer PRO-PN38130

- Edge Protector

- Cord Strap & Tool

- Void Filling Material Machine

- Pick And Place Automation System

- Aluminum Foils

- Strapping Dispenser

- Manual Top Sealer

- Top Sealer TS-250-3P

- Top Sealer TS-150-101SQ

- Top Sealer TS-150-101T

- Top Sealer TS-150-58-2C

- Manual Rotary Cup Sealing Machine

- Top Sealer Ts-300-5p

- Top Sealer Ts-200-69-2c

- Top Sealer Ts-200-80-2c

- Top Sealer Ts-150-123c

- Top Sealer Ts-150-80c

- Top Sealer Ts-150-95c

- Top Sealer Ts-300-8p

- Top Sealer Ts-200-142t-2p

- Top Sealer Ts-200-142t

- Semi Tin Cap Sealing Machine

- Pneumatic Stapler Machine

- PET Strap Dispenser

- Air Boxer, Hand Boxer & Flooring Nailer

- Air Boxer PRO-AB3522COMBI

- Air Boxer PRO-AB3518COMBI

- Flooring Nailer PT Manual XPRO-FN1838 Q500

- Hand Boxer PRO-HB3522COMBI

- Hand Boxer PRO-HB3518COMBI

- Flooring Nailer PT Pneumatic XPRO-FN1838 Q550AL

- Bottom Closer Manual

- Flooring Nailer PT Manual XPRO-FN1650 H330

- Flooring Nailer PT Pneumatic XPRO-FN1650 250F

- Brad Nailer

- Strapping Roll

- Fill Air RF Bag

- Box Strapping Machine

- Bag Closing Machine

- Coding Machine

- Cryovac Shrink Film

- Cup Sealing Machine

- adhesive filling machine

- Pet Strap & Tool

- PP Strap & Tool

- Shrink Chambers, L Sealer With Shrink Tunnel

- Shrink Tunnel

- Web Sealer Shrink Machine

- MPPL06X06 Shrink Tunnel Machine

- Shrink Tunnel Mppl20x12

- Shrink Tunnel Mppl20x20

- Shrink Machine For Water Bottle Label And Cap

- Gas Shrink Gun

- Shrink Tunnel Floor Model Mppl06x06

- Shrink Tunnel MPPL12X12

- Shrink Tunnel Mppl14x16

- Shrink Tunnel Mppl16x12

- Shrink Tunnel Mppl16x16

- Shrink Tunnel Floor Model Mppl08x08

- Shrink Tunnel Floor Model Mppl12x08

- Gas Heat Shrink Gun

- 24X08XX06 Floor Model Shrink Tunnel Machine

- 24X12X08 Shrink Tunnel Machine

- 30X08X06 Floor Model Shrink Tunnel Machine

- 30X12X08 Shrink Tunnel Machine

- 30X12X12 Floor Model Shrink Tunnel Machine

- 30X16X10 Shrink Wrapping Machine

- Leg Type Model Shrink Tunnel Machine

- 36X12X18 Shrink Wrapping Machine

- 36X18X14 Shrink Wrapping Machine

- 39X14X17 Shrinnk Wrapping Machine

- 24X16X8 Shrink Wrapping Machine For Label

- Floor Model Shrink Tunnel Machine

- Shrink Tunnel Floor Model Machine

- Shrink Tunnel Leg Type Model Machine

- Foot Operated Sealer

- Hand Operated Sealer

- Electric Stapler

- Hand Tacker

- Pneumatic Stapler

- Pneumatic Stapler NEO-PS1013J

- Pneumatic Stapler PRO-PS9716

- Pneumatic Stapler PRO-PS8016

- Pneumatic Stapler ECO-PS1013J

- Pneumatic Stapler PRO-PS1013J

- Pneumatic Stapler FA PRO-PSHS16

- Pneumatic Stapler PRO-PS9240

- Pneumatic Stapler NEO-PS10050

- Pneumatic Stapler Prebena XPRO-PS10050

- Pneumatic Stapler OM XPRO-PS8016FA

- Pneumatic Stapler PRO-PS9040

- Pneumatic Stapler ECO-1013JV2

- Pneumatic Stapler PRO-PS10050V2

- Pneumatic Stapler ECO-PS1013F

- Pneumatic Stapler ECO-PS8016LN

- Pneumatic Stapler ECO-PS9040COMBI

- Pneumatic Stapler ECO-PS10050E2

- Pneumatic Stapler FA PRO-PS5416

- Pneumatic Stapler JK XPRO-PS8016RALM

- Pneumatic Stapler NEO-PS8016

- Pneumatic Stapler PRO-PS8016V2

- Pneumatic Stapler ECO-PS8016

- Pneumatic Stapler ECO-PS1013JV2

- Pneumatic Stapler OM XPRO-PS8016

- Pneumatic Stapler PRO-PS8016LNV2

- Pneumatic Stapler ECO-PS7116

- Pneumatic Stapler OM XPRO-PS8016BLM

- Pneumatic Stapler ECO-PS10050

- Pneumatic Stapler OM XPRO-PS8016LN

- Pneumatic Stapler PRO-PS2312

- Pneumatic Stapler PRO-PS9225

- Pneumatic Stapler PRO-PS1013FV2

- Pneumatic Stapler PRO-PS16WC38V2

- Pneumatic Stapler OM XPRO-PS16WC38FA

- Electric Brad Nailer

- Concrete Nailer

- Hammer Tacker

- Pneumatic Corrugated Fastener

- Staple Remover

- Bag Sealing Machine-Impulse Sealer

- 400 FHED Foot Sealer

- 200 FP Foot Operated Sealers Premium Series

- 190 HW Hand Operated Sealers

- AIS 450 Automatic Impulse Sealer

- 300 HW Hand Operated Sealers

- 200 FE Foot Operated Sealers Premium Series

- 400 FD Foot Sealers

- 200 Dv2 Hand Operated Sealers

- 500 FE Foot Operated Sealers

- 900 F Foot Sealers

- 400 FED Foot Operated Sealers

- 200 F Foot Operated Sealers Premium Series

- 900 MSE Mobile Sealing Machine

- 300 HH Hand Operated Hot Bar Sealer

- 300 FPD Foot Sealers

- 300 FP Foot Sealers

- Pneumatic Sealing Machine

- QS400T Impulse Tong Sealer

- 600 FE Foot Sealers

- 400 F Foot Operated Sealers Premium Series

- 300 Delta Hand Operated Sealers

- 600 HB Hand Operated Sealers

- 500 F Foot Sealer

- 400 HB Hand Operated Sealers

- 300 FE Foot Sealers Premium Series

- 300 FD Foot Operated Sealer

- 250 Delta Hand Operated Sealers

- QS300PNI Pneumatic Retort Sealer

- 300 FED Foot Operated Sealers

- QS400TH Hot Bar Tong Sealer

- 300 HB Hand Operated Sealers

- 500 HB Hand Operated Sealers

- QS 300 F Foot Operated Sealers Premium Series

- 200 FH Series Foot Sealer

- 600 F Foot Sealers

- 400 D Hand Operated Sealers

- 200 HB Hand Operated Sealers

- Pneumatic Coil Nailer & Brad Nailer

- Continuous Bag Sealing Band Sealing Machine

- Air Bubble Film Wrap

- Semi-Automatic Box Strapping Machine

- Fully Automatic Strapping Machine

- Hot Air Gun

- Weldy Energy HT3400 Hot Air Hand Tool Machine

- Weldy HG 210 B Hot Air Hand Tool Machine

- Weldy HG 330 A Hot Air Hand Tool Machine

- Weldy HG 330 B Hot Air Hand Tool Machine

- Weldy HG 330 S Hot Air Hand Tool Machine

- Weldy HG 530 A Hot Air Hand Tool Machine

- Weldy HG 530 S Hot Air Hand Tool Machine

- Weldy HT 330 S Hot Air Hand Tool Machine

- Weldy HT 1600 Hot Air Hand Tool Machine

- Weldy HT 1600 D Hot Air Hand Tool Machine

- Weldy HT 530 A Hot Air Hand Tool Machine

- Weldy Energy HT3400 Machine

- Weldy HG 210 B Machine

- Weldy HG 330 A Machine

- Weldy HG 330 B Machine

- Weldy HG 330 S Machine

- Weldy HG 530 A Machine

- Weldy HG 530 S Machine

- Weldy HT 330 S Machine

- Weldy HT 530 A Machine

- Weldy HT 1600 D Machine

- Weldy HT 1600 Machine

- Chamber Type Shrink Machine

- Semi-Automatic Shrink Machine

- Auto Shrink Machine

- Web Shrink Machine

- Mini Model Web Sealer With Shrink Wrapping Machine

- Web Sealer With Shrink Wrapping Machine For Box

- Web Sealer With Shrink Wrapping Machine

- Web Sealer Shrink Wrapping Machine

- Web Sealer with Shrink Wrapping Machine for Box 48 x 48 x 30 Machine

- Web Sealer with Shrink Wrapping Machine for Box

- Web Sealer with Shrink Wrapping Machine Mini Model

- Web Sealer with Shrink Wrapping Machine

- Continuous Bag Sealer

- Automatic Plastic Bag Vertical Band Sealer

- PSCH7200 Heavy Duty Horizontal Continuous Pouch Sealer

- SCS 3H Smart Continuous Sealer Horizontal

- Vertical Continous Bag Sealing Machine

- Vertical Continous Bag Sealing Machine

- CS Series Continuous Sealer Gas Flushing

- Vertical Continuous Sealer

- Jack Type Vertical Continuous Sealer Machine

- Vertical Heavy Duty Continuous Pouch Sealer Machine

- 8 Continuous Bag Sealer

- Continuous Pouch Sealer Heavy Duty Horizontal

- Continuous Pouch Sealer Heavy Duty Vertical

- Continuous Pouch Sealer Heavy Duty

- Continuous Sealer Gas Flushing

- Continuous Sealer Horizontal

- Continuous Sealer Vertical Model for 20 Kg

- Continuous Sealer Vertical

- Jack type Vertical Continuous Sealer Machine

- AQD 19 Pneumatic Pet PP Strap Tool

- Induction Sealing Machine

- Air Cool Induction Cap Sealing Machine

- IS 50C 120C Induction Sealers

- IS 80P Induction Sealers

- IS 130C Induction Sealers

- Manual Foil Sealing Machine

- Air Cool Induction Cap Sealing Machine

- IS 50C 120C Induction Sealing Machine

- IS 80P Induction Sealing Machine

- IS 130C Induction Sealing Machine

- Manual Foil Sealing Machine

- Induction Wad Sealing Machine

- Hand Sealer Pedal Machine

- Vacuum Packaging Machine

- Labelling Machine

- Top Sealer

- Printing Machine

- Packing Materials

- Air Bubble Roll

- Clear Air Bubble Roll

- Aluminium Foil

- Printed Round Aluminium Foil

- BOPP Tape

- Steel Buckle

- Cord Strap Buckle

- Cord Strap

- Edge Protector

- Brown Edge Protector

- Glue Stick

- Induction Wad For Cap

- Round Induction Wad

- LDPE Roll

- Clear LDPE Roll

- PET Strap

- Polyole Roll

- Clear Polyole Roll

- Transparent Polyole Roll

- PP Strap

- PET Preform

- PVC Shrink Roll

- PVC Shrink Sleeve

- Serrated Seals And Seals

- Stretch Film

- White Thread

- Vacuum Pouch

- Rectangular Vacuum Pouch

- Transparent Vacuum Pouch

- BOPP Tape Dispenser

- Wad And Foils

- Hand Tools

- Contact Us

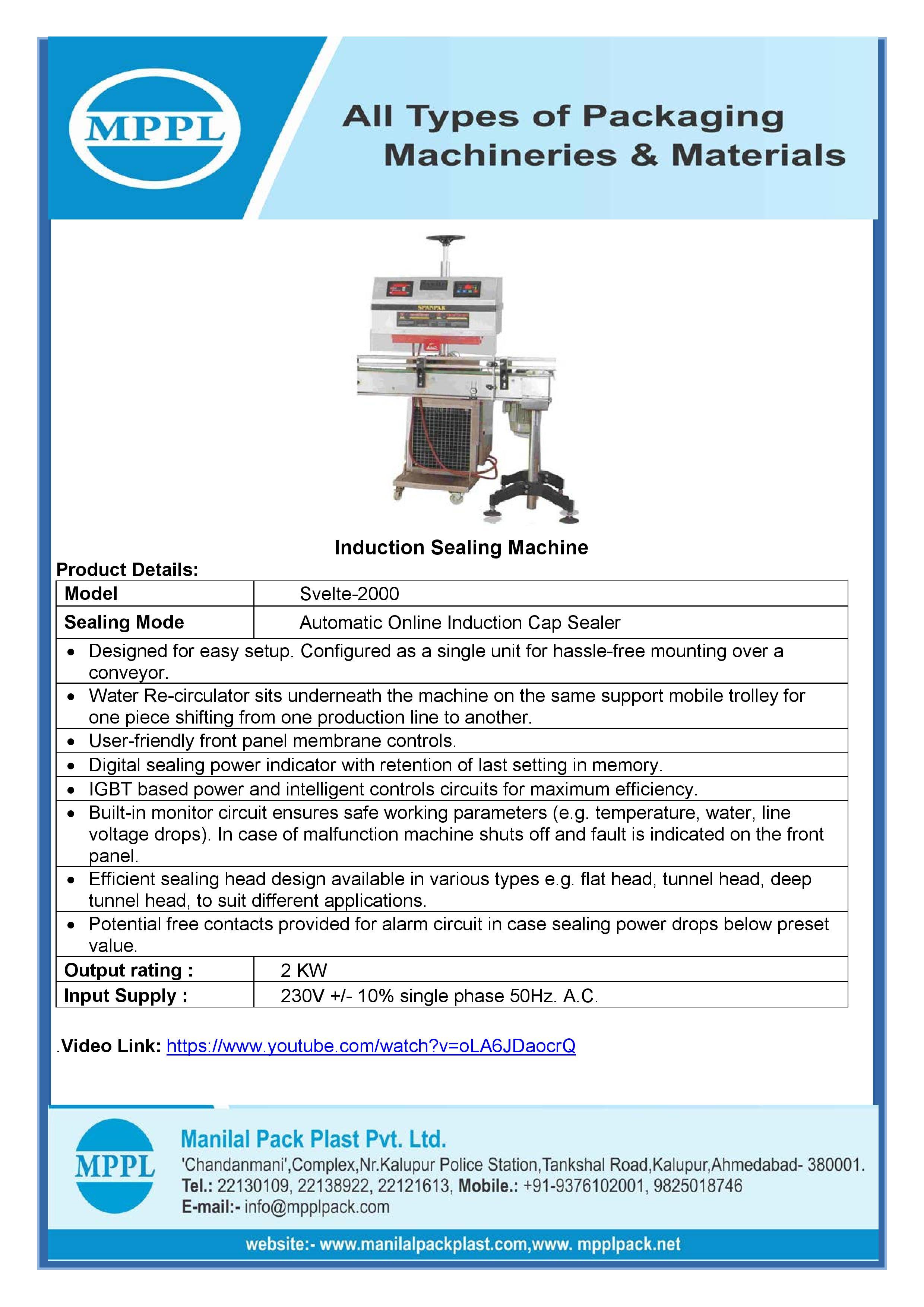

Induction Sealing Machine 2000

250000.00 INR/Unit

Product Details:

- Color White/Grey

- Voltage 220V, 50 Hz

- Automation Grade Automatic

- Driven Type Electric

- Accuracy High precision electronic control

- Power 2 kW

- Dimension (L*W*H) 1150 x 480 x 390 mm

- Click to View more

X

Induction Sealing Machine 2000 Price And Quantity

- 250000.00 INR/Unit

- 1 Unit

- Microprocessor Based

- Air Cooled

- Continuous

- Adjustable

- 20-100 mm

- 50/60 Hz

- Stainless Steel

- Digital/LED Indication

- Overload/Overheat Protection

Induction Sealing Machine 2000 Product Specifications

- 20-200 bottles/min

- Induction Sealing

- 1150 x 480 x 390 mm

- 2 kW

- Electric

- High precision electronic control

- Automatic

- White/Grey

- 220V, 50 Hz

- Plastic, Glass Bottles with Foil Seals

- 68 kg

- Automatic Online Induction Cap Sealer

- 20-200 bottles/min

- Sealing Caps on Bottles (Plastic, Glass)

- 0-12 m/min

- New

- Adjustable, up to 100 mm Dia Cap

- Up to 200 bottles per minute

- Automatic Online Induction Cap Sealer

- Microprocessor Based

- Air Cooled

- Continuous

- Adjustable

- 20-100 mm

- 50/60 Hz

- Stainless Steel

- Digital/LED Indication

- Overload/Overheat Protection

Induction Sealing Machine 2000 Trade Information

- Cash Advance (CA)

- 10-15 Days

- Asia

- All India

Product Description

Product Details

| Model | Svelte-2000 |

| Sealing Mode | Automatic Online Induction Cap Sealer |

| Designed for easy setup. Configured as a single unit for hassle-free mounting over a conveyor. | |

| Water Re-circulator sits underneath the machine on the same support mobile trolley for one piece shifting from one production line to another. | |

| User-friendly front panel membrane controls. | |

| Digital sealing power indicator with retention of last setting in memory. | |

| IGBT based power and intelligent controls circuits for maximum efficiency. | |

| Built-in monitor circuit ensures safe working parameters (e.g. temperature, water, line voltage drops). In case of malfunction machine shuts off and fault is indicated on the front panel. | |

| Efficient sealing head design available in various types e.g. flat head, tunnel head, deep tunnel head, to suit different applications. | |

| Potential free contacts provided for alarm circuit in case sealing power drops below preset value. | |

| Output rating : | 2 KW |

| Input Supply : | 230V +/- 10% single phase 50Hz. A.C. |

Product VideoLink: https://www.youtube.com/watch?v=oLA6JDaocrQ

High-Efficiency Sealing Solution

Engineered for industrial-scale performance, the Induction Sealing Machine 2000 automates and streamlines the process of sealing caps on plastic and glass containers. Its advanced microprocessor-based system ensures exceptionally consistent results, ideal for manufacturers and suppliers aiming to boost productivity and maintain packaging integrity. Overload and overheat protections give operators confidence in safe, continuous running.

Versatile and User-Friendly Design

This cap sealer offers a flexible approach with an adjustable conveyor height, suitable for a wide range of bottle sizes and cap diameters. Operators benefit from intuitive digital/LED indications and simple adjustments, while the air-cooled setup minimizes maintenance needs. The machines durability and precision control make it a dependable addition to any production line.

FAQs of Induction Sealing Machine 2000:

Q: How does the Induction Sealing Machine 2000 work?

A: The Induction Sealing Machine 2000 uses electromagnetic induction to heat and bond foil seals onto plastic or glass bottles. As bottles pass through the conveyor, the induction head generates a magnetic field that heats the foil liners, sealing them to the bottle mouths quickly and securely.Q: What types of bottles can this machine seal?

A: This machine is suitable for plastic and glass bottles with diameters ranging from 20 mm to 100 mm and cap sizes up to 100 mm, making it ideal for a variety of industries including pharmaceuticals, food, and beverages.Q: When is it beneficial to use an automatic online induction cap sealer like this?

A: It is particularly beneficial when high-speed, continuous bottle sealing is required. With an operational speed of 20200 bottles per minute, it is perfect for production environments that demand efficiency, consistency, and secure packaging.Q: Where can the Induction Sealing Machine 2000 be installed?

A: This machine is designed for use in factories, production plants, and packaging facilities in India and globally. Its compact dimensions (1150 x 480 x 390 mm) and adjustable conveyor height make it easy to integrate into most production lines.Q: What is the process for setting up and adjusting the sealing parameters?

A: Operators can adjust the conveyor height and sealing length through accessible controls. The digital/LED display provides clear operational information, while the microprocessor-based control system ensures high precision in setting and maintaining parameters for various bottle and cap sizes.Q: How does the safety mechanism protect the machine and operator?

A: The integrated overload and overheat protection mechanisms automatically halt operation if unsafe conditions are detected, thereby preventing equipment damage and enhancing operator safety.Q: What are the main benefits of using this automatic induction sealing machine?

A: Key benefits include reliable sealing, high production throughput, precise electronic control, easy operation, and enhanced safety. Its automatic and continuous operation reduces manual labor and helps maintain product freshness and tamper evidence.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese